Kao Chemicals Europe develops, manufactures and supplies a wide range of raw materials for high-performing industrial paint and coating formulations. Our additive portfolio includes customized dispersants for pigment grinding and stabilization, emulsifiers, and specialty additives. These superior products find applications in architectural, automotive OEM, and various industrial coatings, ensuring the delivery of exceptional results across diverse sectors.

Paints and Coatings Solutions

Advanced industrial paint and coating solutions that improve performance and care for the environment.

Our applications

Pigment Dispersion

Effective dispersing agents for inorganic and organic pigments.

The dispersion of solid pigments or fillers into the liquid phase of binder solutions is an important step in the preparation of industrial paint and coatings. The dispersion level has a direct influence on optical properties, such as colour strength, transparency, and gloss as well as physical properties, such as rheology, stability and flocculation.

Pigment dispersion control additives are used to improve and accelerate the dispersion process and to stabilize the formulation during storage.

Dispersion control additives also play a crucial role in ensuring good performance throughout the lifecycle of paint, from production and storage to application and film properties.

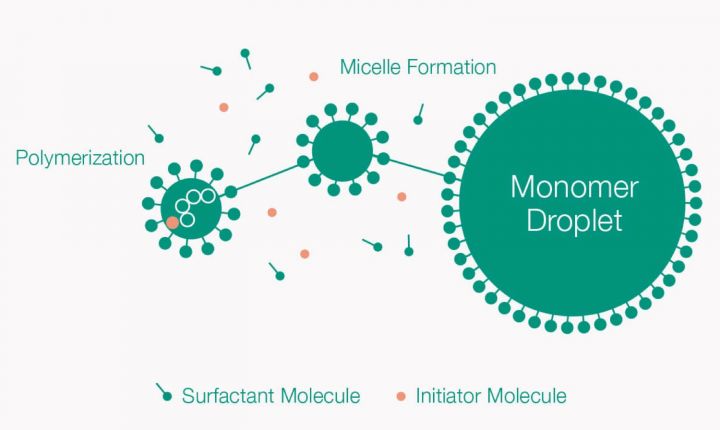

Emulsion Polymerization

Emulsifiers for emulsion polymerization

Kao Chemicals offers a full range of surfactants for emulsion polymerization based on our core technologies of sulfonation, alkoxylation, and phosphorylation. AKYPO, MELIOSOL, and LATEMUL are used in the production of acrylics, vinyl acetates, polyvinyl chlorides, styrene butadiene, and alkyds. Kao Chemical’s portfolio includes anionic and non-ionic emulsifiers with improved environmental profile (APEO free and low VOC).

Kao Chemicals surfactants provide efficiency, consistency and high performance regarding industrial paints and coatings. Important attributes for the emulsion polymerization process and end-use applications, including good polymerization kinetics, particle size and distribution control, water resistance, improved electrolyte and freeze-thaw stability, as well as reduced grid formation.